Shaded Pole Motor, C-Frame Motor Manufacturer

- C-Frame, O-Frame, 3.3″ and nonstandard frame size

- 1/100HP – 1/5Hp

- 1300-3200 RPM (2/4 magnetic poles)

- Single and multi-speed

- Approval: UL/CSA

A Shaded Pole motor is a single phase induction motor. Just like any other single phase motor, it is not self-starting and is provided with a special arrangement to generate the rotating magnetic field. However, unlike PSC motors and split phase motors – a shaded pole motor does not have any capacitors or a centrifugal switch. Instead, a shaded pole motor uses an auxiliary winding which is basically a copper ring surrounding a portion of each pole to generate the starting torque. The design of a Shaded Pole motor is very basic, which makes it very easy to manufacture. GEMS not only provide a complete range of standard and custom C-frame shaded pole motors but also offer a large selections of shaded pole motors driven cross-flow/tangential fans, squirrel cage fans, axial fans, blowers and small pumps, such as the direct replacement kits of Broan ventilation fans. We leverage our large manufacturing network in China to provide the most cost-effective C-frame shaded pole motor and fan solutions for our customers.

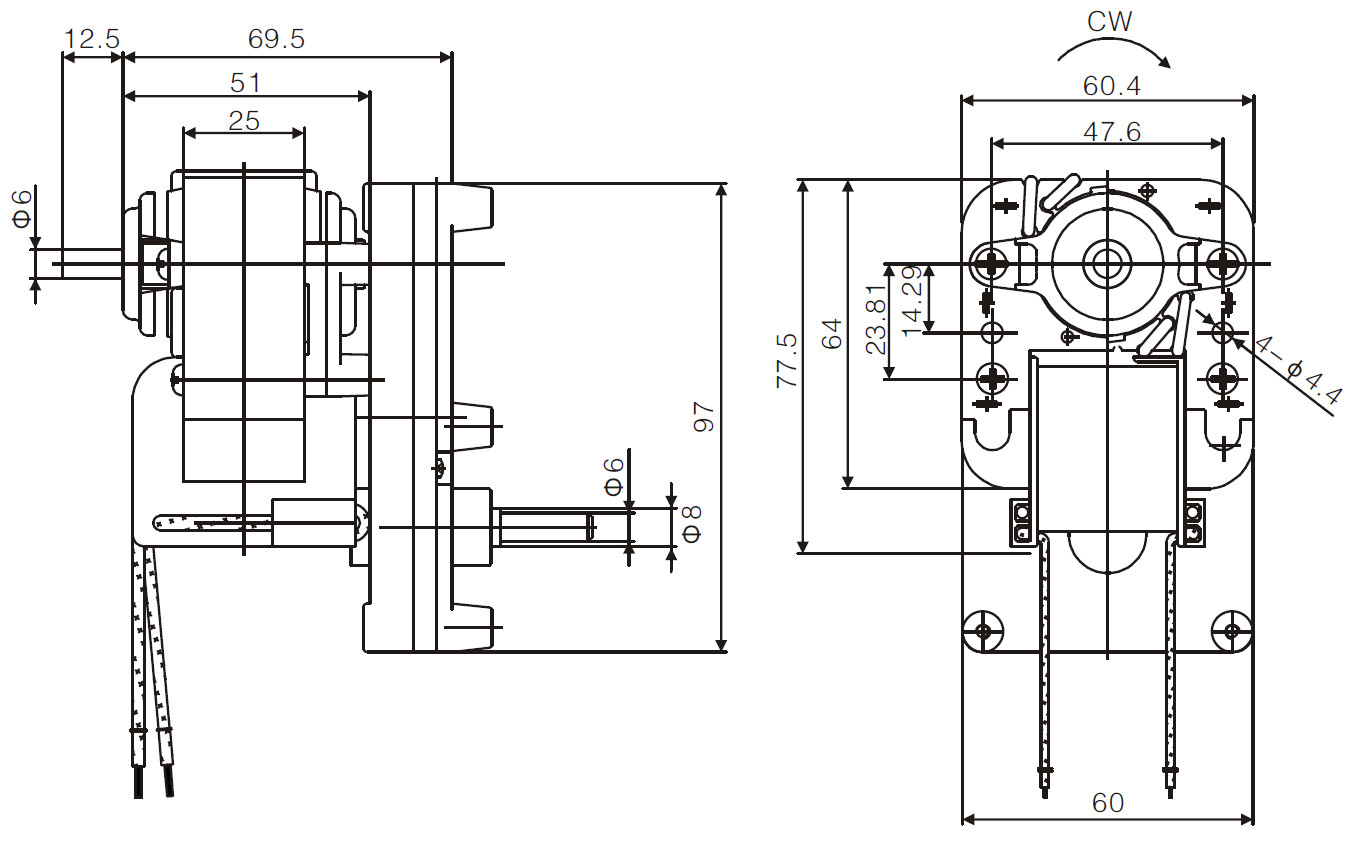

YJF48/ 48mm C-frame Shaded Pole Motor

Rated Power 1/100 HP – 1/30 HP, Rated Speed 1500 rpm – 3000 rpm

| Model | Voltage | Frequency | Current | Watts | HP | Rated RPM | Torque (mN.m) | Stack Length (mm) | Shaft Length (mm) |

|---|---|---|---|---|---|---|---|---|---|

| YJF48/08-2 | 220/120 | 50/60 | 0.09 | 7.2 | 1/105 | 2100 | 2.3 | 8 | 10-200 |

| YJF48/10-2 | 220/120 | 50/60 | 0.1 | 7.5 | 1/100 | 2100 | 2.5 | 10 | 10-200 |

| YJF48/12-2 | 220/120 | 50/60 | 0.11 | 10.5 | 1/70 | 2150 | 3 | 12 | 10-200 |

| YJF48/16-2 | 220/120 | 50/60 | 0.14 | 15.5 | 1/50 | 2200 | 4 | 16 | 10-200 |

| YJF48/20-2 | 220/120 | 50/60 | 0.15 | 19 | 1/40 | 2250 | 5.4 | 20 | 10-200 |

| YJF48/25-2 | 220/120 | 50/60 | 0.18 | 22.8 | 1/33 | 2250 | 6.5 | 25 | 10-200 |

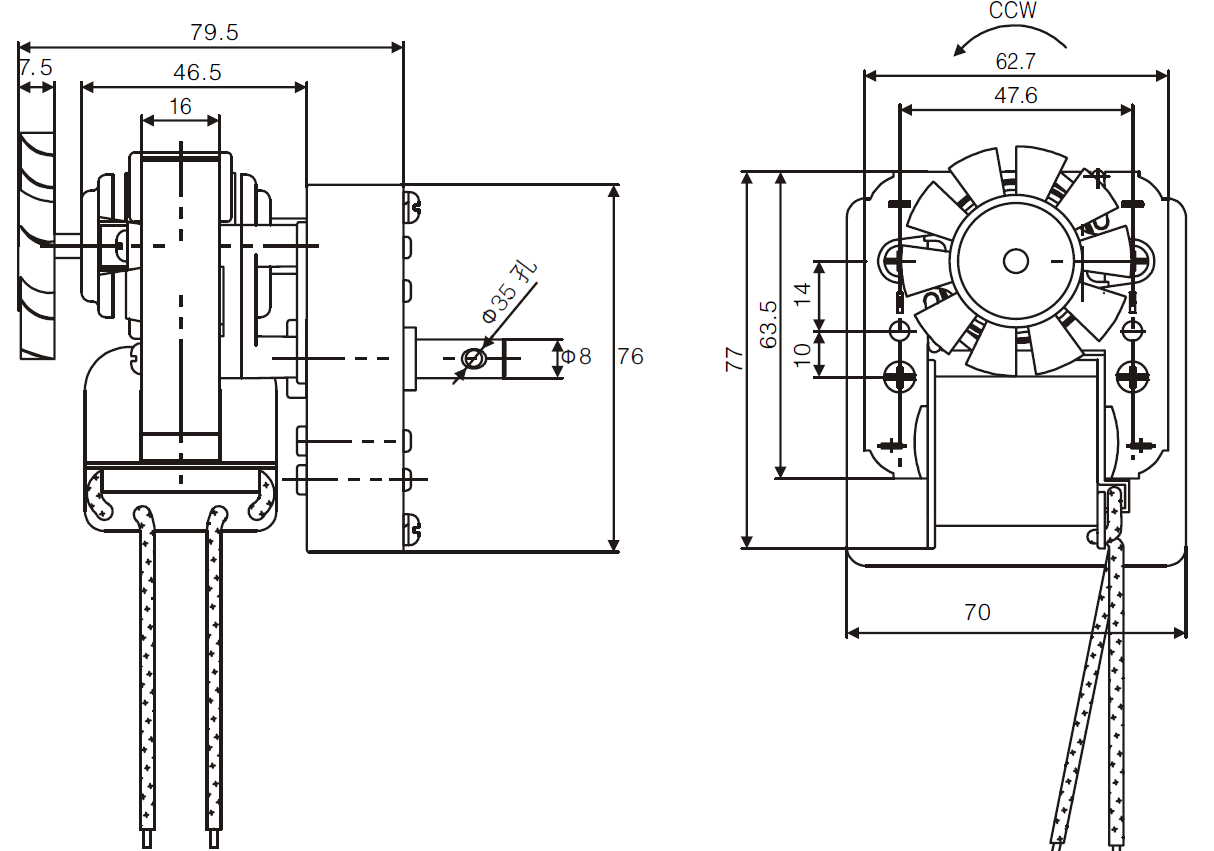

YFJ61/ 61mm C-frame Shaded Pole Motor

Rated Power 1/50 HP – 1/30 HP, Rated Speed 1550 rpm – 3100 rpm

| Model | Voltage | Frequency | Current | Watts | HP | Rated RPM | Torque (mN.m) | Stack Length (mm) | Shaft Length (mm) |

|---|---|---|---|---|---|---|---|---|---|

| YJF61/10-2 | 220/120 | 50/60 | 0.15 | 15 | 1/50 | 2300 | 5.9 | 8 | 10-200 |

| YJF61/13-2 | 220/120 | 50/60 | 0.17 | 17.5 | 1/40 | 2300 | 8.8 | 10 | 10-200 |

| YJF61/14-2 | 220/120 | 50/60 | 0.19 | 20 | 1/35 | 2350 | 12.8 | 12 | 10-200 |

| YJF61/16-2 | 220/120 | 50/60 | 0.2 | 23 | 1/33 | 2350 | 14.7 | 16 | 10-200 |

| YJF61/20-2 | 220/120 | 50/60 | 0.21 | 25 | 1/30 | 2500 | 16.6 | 20 | 10-200 |

YJF61- 61mm C-frame Shaded Pole Motor

Rated Power 1/25 HP – 1/18 HP, Rated Speed 1600 rpm – 3200 rpm

| Model | Voltage | Frequency | Current | Watts | HP | Rated RPM | Torque (mN.m) | Stack Length (mm) | Shaft Length (mm) |

|---|---|---|---|---|---|---|---|---|---|

| YJF61/26-2 | 220/120 | 50/60 | 0.25 | 28 | 1/25 | 2550 | 19.6 | 26 | 10-200 |

| YJF61/30-2 | 220/120 | 50/60 | 0.29 | 31 | 1/24 | 2600 | 23 | 30 | 10-200 |

| YJF61/35-2 | 220/120 | 50/60 | 0.32 | 34 | 1/22 | 2600 | 26.5 | 35 | 10-200 |

| YJF61/40-2 | 220/120 | 50/60 | 0.38 | 41 | 1/18 | 2600 | 29.5 | 40 | 10-200 |

YJF55/ 55mm C-frame Shaded Pole Motor

1/60 HP (12.5 watts) – 1/33 HP (23 watts), 1650 RPM – 3200 RPM

| Model | Voltage | Frequency | Current | Watts | HP | Rated RPM | Torque (mN.m) | Stack Length (mm) | Shaft Length (mm) |

|---|---|---|---|---|---|---|---|---|---|

| YJF55/18-2 | 220/120 | 50/60 | 0.12 | 12.5 | 1/60 | 2300 | 8.9 | 18 | 10-200 |

| YJF55/24-2 | 220/120 | 50/60 | 0.19 | 23 | 1/33 | 2400 | 14.7 | 24 | 10-200 |

YJF71/ 71mm C-frame Shaded Pole Motor

1/18 HP (42 watts) – 1/10 HP (78 watts), 1750 RPM – 3300 RPM

| Model | Voltage | Frequency | Current | Watts | HP | Rated RPM | Torque (mN.m) | Stack Length (mm) | Shaft Length (mm) |

|---|---|---|---|---|---|---|---|---|---|

| YJF71/20-2 | 220/120 | 50/60 | 0.39 | 42 | 1/18 | 2400 | 41 | 20 | 10-200 |

| YJF71/25-2 | 220/120 | 50/60 | 0.49 | 53 | 1/15 | 2400 | 51.2 | 24 | 10-200 |

| YJF71/30-2 | 220/120 | 50/60 | 0.55 | 60 | 1/12 | 2400 | 57.9 | 30 | 10-200 |

| YJF71/35-2 | 220/120 | 50/60 | 0.59 | 65 | 1/11 | 2400 | 62 | 35 | 10-200 |

| YJF71/40-2 | 220/120 | 50/60 | 0.63 | 68 | 1/11 | 2400 | 65.6 | 40 | 10-200 |

| YJF71/45-2 | 220/120 | 50/60 | 0.71 | 78 | 1/10 | 2400 | 75 | 45 | 10-200 |

YJF58/ 58mm C-frame Shaded Pole Motor

1/50 HP (15 watts) – 1/30 HP (23 watts) , 1450 rpm – 2800 rpm

| Model | Voltage | Frequency | Current | Watts | HP | Rated RPM | Torque (mNm) | Stack Length | Shaft Length |

|---|---|---|---|---|---|---|---|---|---|

| YJF58/12-2 | 220/120 | 50/60 | 0.14 | 15.5 | 1/50 | 2250 | 4 | 12 | 10-200 |

| YJF58/16-2 | 220/120 | 50/60 | 0.17 | 17.5 | 1/40 | 2300 | 9 | 16 | 10-200 |

| YJF58/20-2 | 220/120 | 50/60 | 0.2 | 23 | 1/30 | 2340 | 15 | 20 | 10-200 |

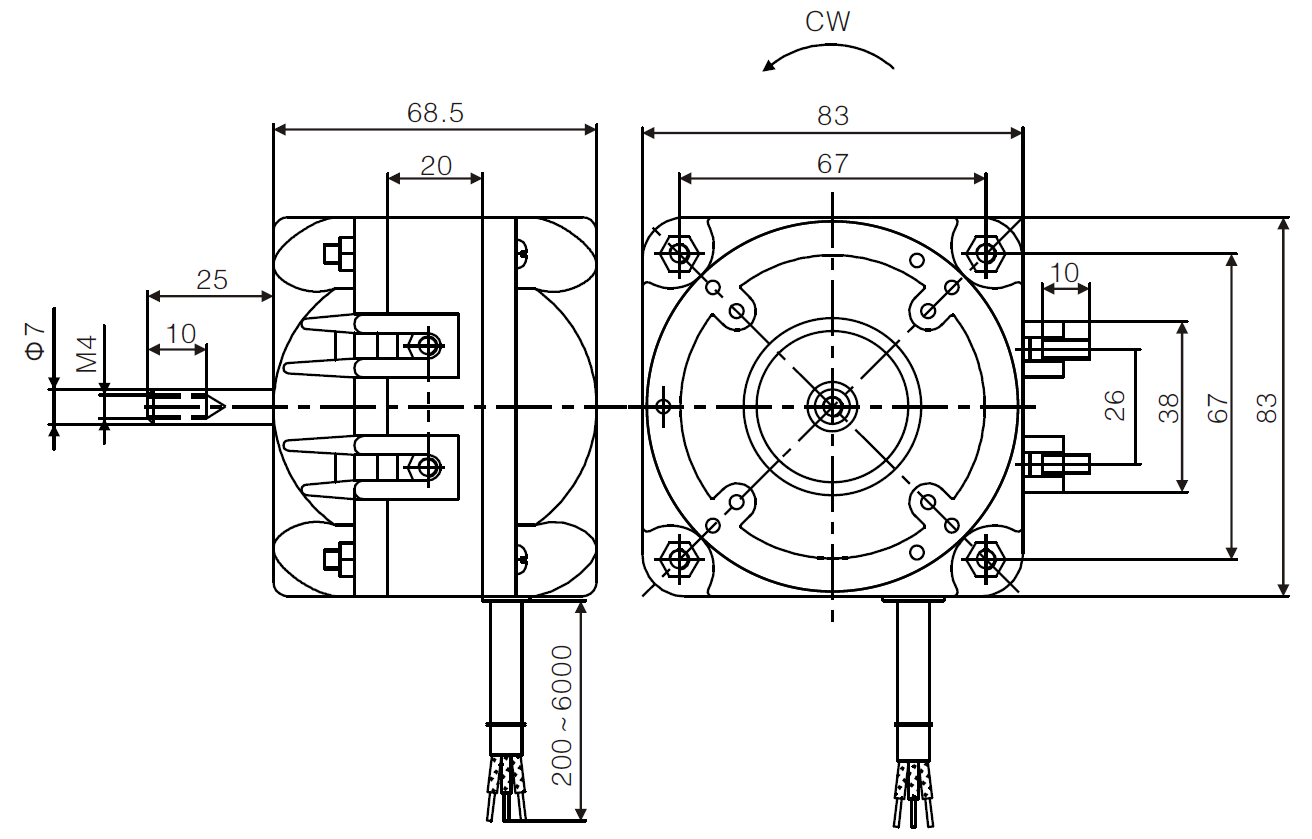

YJF82/ 82mm C-frame Shaded Pole Motor

1/20 HP (40 watts) – 1/10 HP (75 watts) , 1300 RPM – 2950 RPM

| Model | Voltage | Frequency | Current | Watts | HP | Rated RPM | Stack Length (mm) | Shaft Length (mm) |

|---|---|---|---|---|---|---|---|---|

| YJF82/13-2 | 220/120 | 50/60 | 0.28 | 39 | 1/20 | 1300 | 13 | 10-200 |

| YJF82/20-2 | 220/120 | 50/60 | 0.32 | 46 | 1/16 | 1300 | 20 | 10-200 |

| YJF82/25-2 | 220/120 | 50/60 | 0.47 | 65 | 1/12 | 1300 | 25 | 10-200 |

84mm C-frame Shaded Pole Motor

1/6 HP (127 watts) – 1/5 HP (145 watts) , 1750 RPM – 3000 RPM

| Model | Voltage | Frequency | Current | Watts | HP | Rated RPM | Stack Length (mm) | Shaft Length (mm) |

|---|---|---|---|---|---|---|---|---|

| YJF84/25-2 | 220/120 | 50/60 | 1.02 | 127 | 1/6 | 2300 | 25 | 10-200 |

| YJF84/30-2 | 220/120 | 50/60 | 1.2 | 145 | 1/5 | 2300 | 30 | 10-200 |

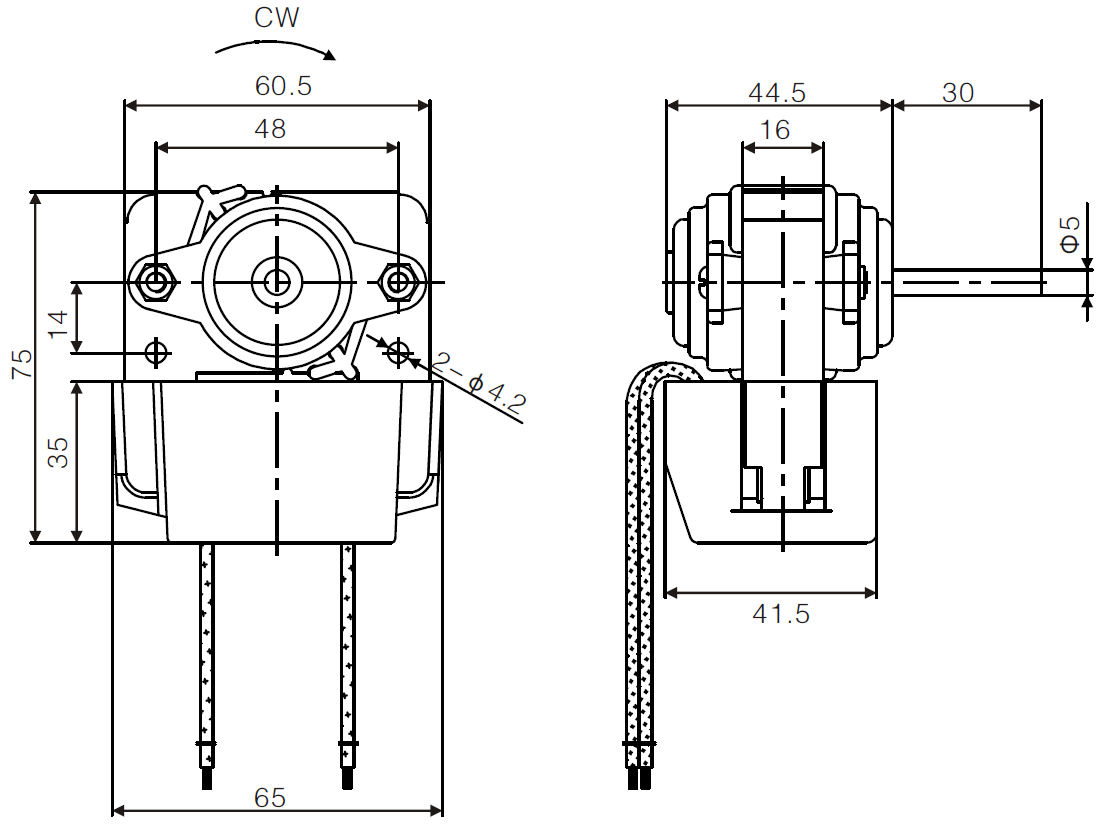

AC Refrigerator Fan Motor

1/115 HP (6.5 watt) – 1/35 HP (20.5 watt) , 1750 RPM – 3400 RPM

| Model | Voltage | Frequency | Current | Watts | HP | Rated RPM | Torque (mN.m) | Stack Length (mm) | Shaft Length (mm) |

|---|---|---|---|---|---|---|---|---|---|

| YJF61/10 | 220/115 | 50/60 | 0.06 | 6.5 | 1/115 | 2450 | 4 | 10 | 10-200 |

| YJF61/13 | 220/115 | 50/60 | 0.2 | 12 | 1/60 | 2900 | 9 | 14 | 10-200 |

| YJF61/16 | 220/115 | 50/60 | 0.2 | 20.5 | 1/35 | 2600 | 15 | 16 | 10-200 |

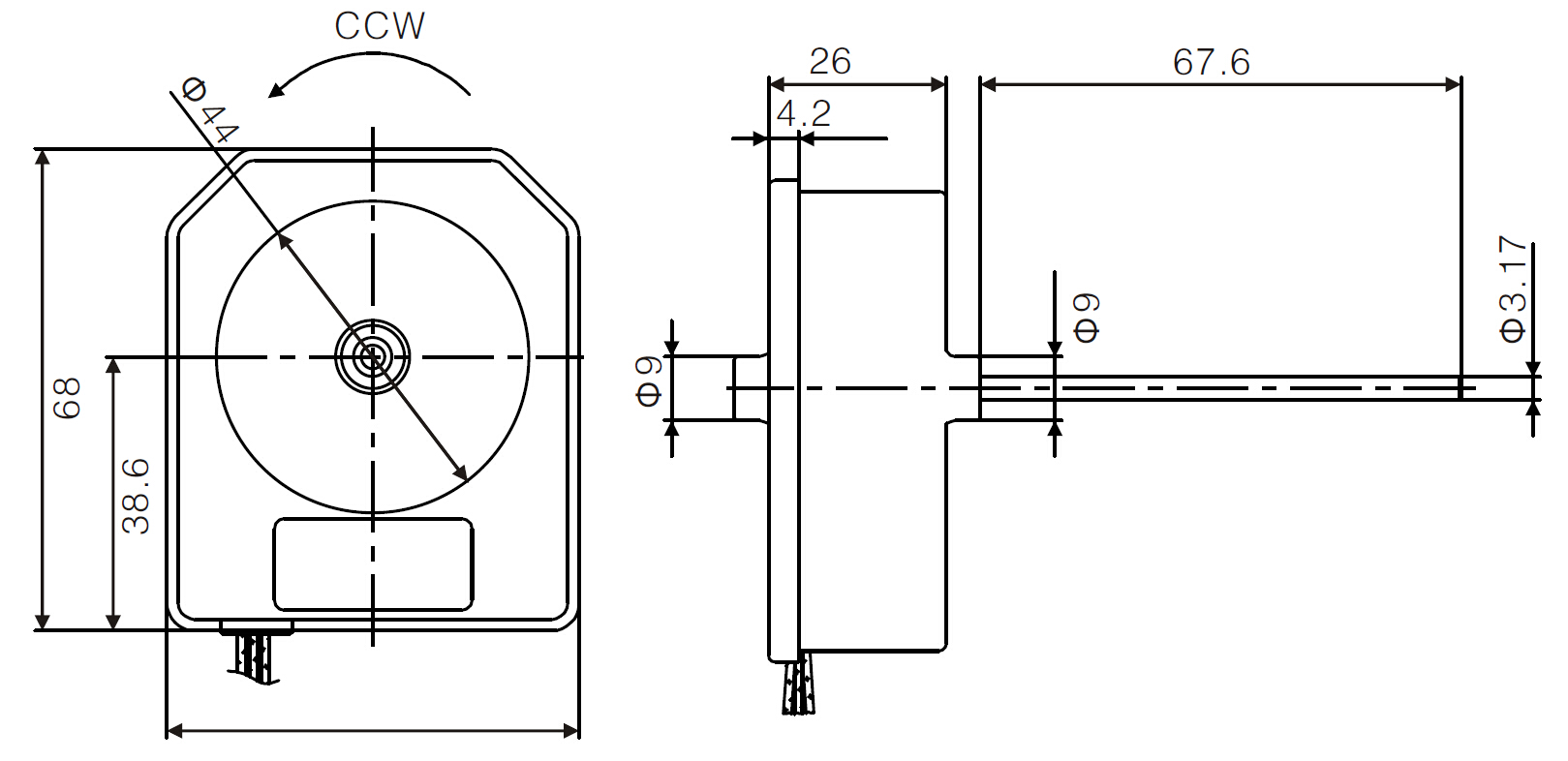

ECM REFRIGERATOR EVAPORATOR FAN MOTOR

1/400 HP (2 watts) – 1/150 ( 5 watts) , 1625 RPM – 3300 RPM

| Model | Voltage | No Load Current | No Load Power | Rated Current | Rated Power | HP | Rated RPM | Shaft Length (mm) |

|---|---|---|---|---|---|---|---|---|

| ZW58/05A | 9.75 VDC | 0.084 | 0.83 | 0.185 | 1.8 | 1/400 | 3025 | 10-200 |

| ZW58/05B | 12 VDC | 0.066 | 0.8 | 0.25 | 3 | 1/250 | 2580 | |

| ZW58/05C | 12 VDC | 0.068 | 0.8 | 0.237 | 2.8 | 1/270 | 2540 |

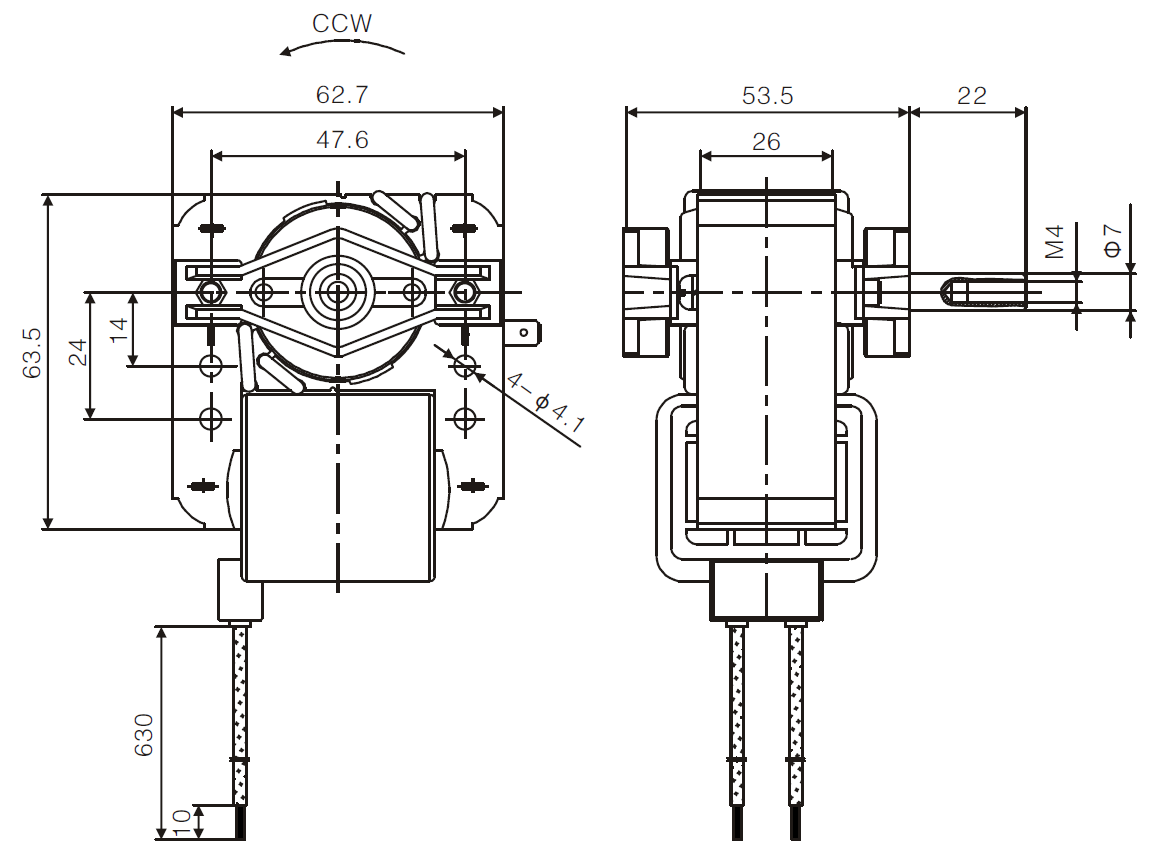

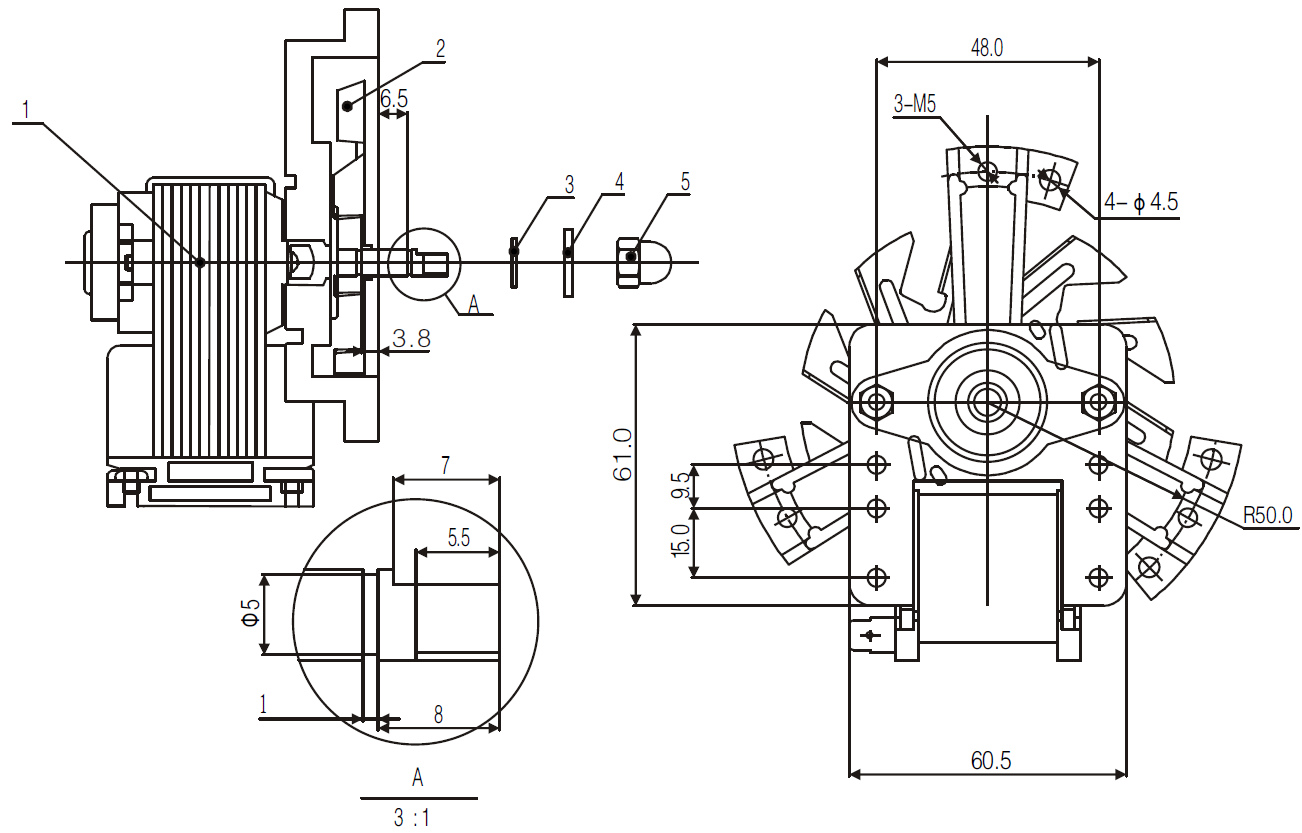

Convection Oven Fan Motor

1/50 HP (15 watts) – 1/10 (75 watts) , 1500 RPM – 3250 RPM

| Model | Voltage | Frequency | Current | Watts | HP | Rated RPM | Stack Length (mm) | Shaft Length (mm) |

|---|---|---|---|---|---|---|---|---|

| YJF61/20-OV | 220/120 | 50/60 | 0.2 | 25 | 1/30 | 1900 | 20 | 10-200 |

| YJF61/30-OV | 220/120 | 50/60 | 1.25 | 71 | 1/10 | 3250 | 30 | 10-200 |

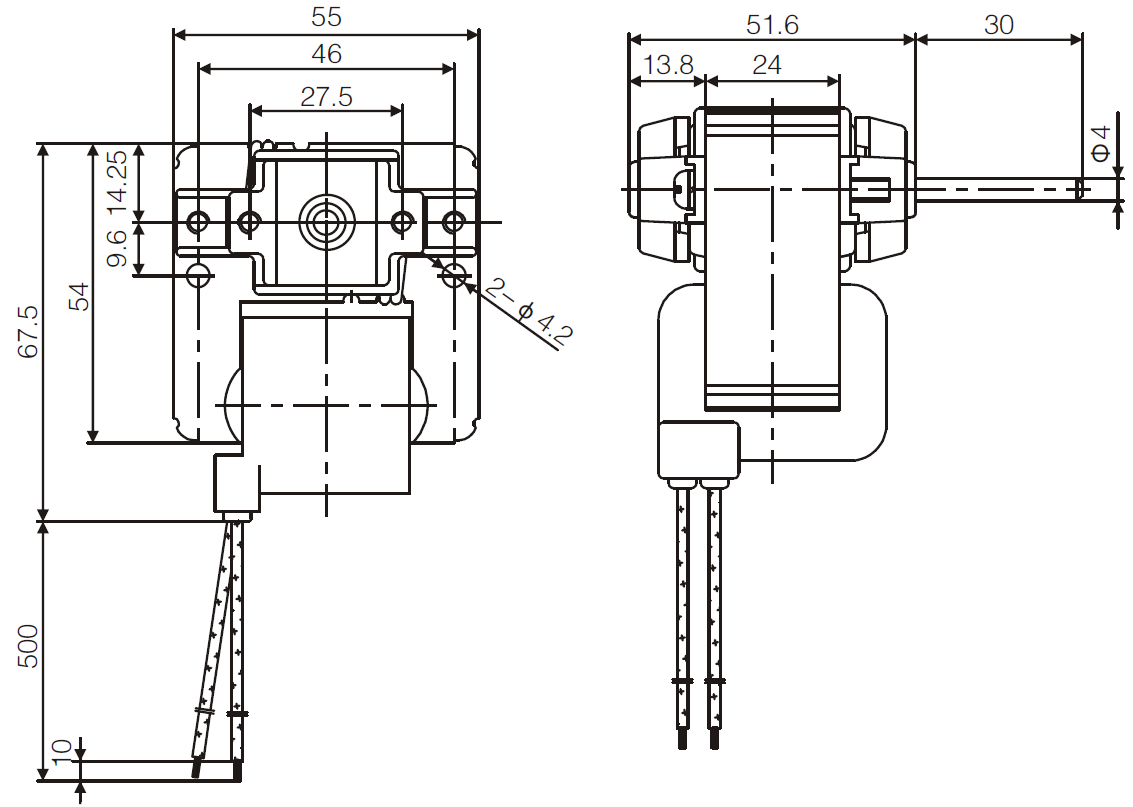

Auger Gear Motors for Pellet Stoves and Grills – 1 RPM~20 RPM.

Rated Power Output 20W- 40W

Axial Fans, Ventilation Fans, Exhaust Fans, Attic Fans

Various types of fans, mounting accessories and waterproof ratings are available upon request

Air-conditioner Condensate Pump and Motor

1/80 – 1/12 HP

What is Shaded Pole Motor

Construction:

A Shaded Pole motor consists of Salient poles connected to the Stator Winding and a squirrel cage type rotor. The poles are constructed in a way that moving magnetic field is produced. Each pole in a Shaded pole motor can be divided into two parts:

- Shaded Part

- Un-Shaded Part

In the shaded region, a slot is cut out at about one third distance from the edge and a heavy copper rings (Which is also known as shading coil) is placed. The remaining portion of the pole is known as Un-Shaded region. The presence of a copper coil influences the presence of flux in the shaded part of the pole.

The squirrel cage type rotor contains long conductive bars (Generally of copper or aluminum) which are mounted into the grooves of a shaft. These bars are connected at both the ends by conducting rings, creating a cage like structure. The name is derived from the similarity of the setup to a squirrel cage.

Working:

When Alternating Current is supplied to a Shaded Pole motor, an alternating flux is produced which causes induction of EMF in the shaded region. Because the shaded region is short circuited, the production of current is in opposite direction to that of the main flux. The flux produced in unshaded region leads that in the shaded region. And a net rotating flux is generated due to the phase difference between these two fluxes. However, as the current supplied to the stator winding is alternating in nature, so is the flux. To have a deeper understanding of the working of a Shaded pole motor, we need to understand three stages which a shaded pole motor goes through during its positive half cycle:

- When the value of flux goes from zero to nearly its maximum positive value.

- When the flux remains constant at its maximum positive value.

- When the flux reduces its value from maximum to zero.

Stage 1:

At this stage, the value of flux goes from zero to nearly max value. Since the rate of change of flux in this stage is very high, the current is also very high. As per the Faradays law, change in flux leads to induction of emf and as our copper ring in the shaded region is short circuited, there is a flow of current due to this induced emf which in turn, produces its own flux. Now, this current follows Lenz’s law and flows in such as direction that it opposes its cause. Now the flux generated in the copper ring starts to oppose the main flux. This creates a disparity in the strength of flux present in the shaded and unshaded region with the value of flux being higher in the unshaded region. This disturbance and uneven distribution of flux between the two regions causes a shift in the magnetic axis in the middle of the unshaded region.

Stage 2:

During this stage, the rate of rise in current and the flux remains almost constant at the maximum value. Therefore, very little emf is induced in the shaded region. The flux produced in this stage has little to no effect on the main flux. As a result, the disparity in the values of flux in both the regions remains negligible and the distribution of flux is uniform. Due to uniform distribution of flux, magnetic axis lies at the center of the pole.

Stage 3:

In this stage, the flux starts to decrease from its max value to zero. In principle, this stage is similar to Stage 1 but opposite in nature. Here also, the change in flux causes induction of emf (As per Faraday’s Law). And this induced emf causes the flow of current in the short circuited copper ring. And the current produced in the copper ring is in such a direction that it opposes its cause (According to Lenz’s Law) but in this stage, its cause is decrease in flux. So, the flux generated in shaded region aids the main flux. As a result, the flux is more powerful in the shaded region than the unshaded region which leads to a shift in magnetic axis towards the center of the shaded region.

As you can see, the magnetic axis was at the center of the unshaded region in Stage 1 and it shifted to the center of the pole in Stage 2 and finally in stage 3, it was in the middle of shaded region. This shifting of magnetic axis continues in the negative cycle as well when the flux –

- Goes from Zero to nearly maximum negative value.

- Is constant at maximum negative value.

- Goes from maximum negative value to zero.

This continuous shift in Magnetic Axis leads to the production of a rotating magnetic field which is required to keep the rotor spinning.

Advantages of a Shaded Pole Motor:

- Since its construction is pretty simple, it is very cheap to manufacture and does not require a large investment to begin production.

- Due to the absence of complex mechanisms and parts such as centrifugal switches, et cetera, it is very robust, reliable and can endure a lot of abuse.

- Due to the lack of any start winding, the primary winding is heavy enough to carry large amount of current in case the rotor gets stuck and stops spinning. In such scenario, the motor will only overheat and not burn. This provides burnout protection without any extra equipment.

Disadvantages of a Shaded Pole Motor:

- The starting torque is low.

- It is not very efficient because of copper losses are high due to the presence of copper band.

- Reversal in spinning is difficult and expensive to implement as it would require additional set of copper rings.

- It has a low power factor.